Billets

Our special steel's origin: billets from Acciaierie di Calvisano

We produce billets in our continuous casting process from high-quality steel.

Acciaierie di Calvisano is part of Feralpi Group and the Business Unit Specialties, producing billets for the production of high-value-added steels that are rolled at Caleotto. The billets are the result of state-of-the-art production processes and constant attention to research and innovation. This winning combination ensures products that guarantee strength, reliability, and optimal performance in any application context.

Billets are the starting point for the production of a wide range of steel products. And, of course, also for our steels. Each billet contains its own quality recipe that differentiates it in terms of quality and use.

Through post-furnace treatment and after rigorous control of chemical composition, all classes of fine-grained steels, controlled sulfur steels, alloyed steels, and microalloyed steels are produced.

Quality control is fundamental.

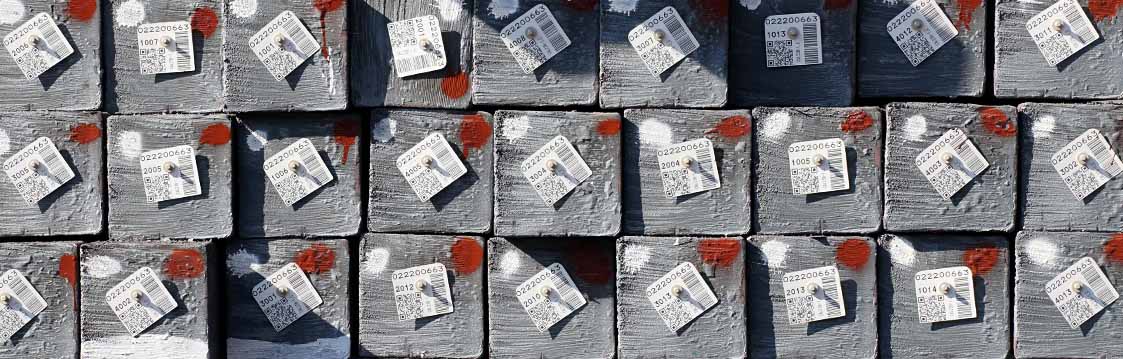

Acciaierie di Calvisano is equipped with a billet tracking system using two labelling robots, which provide information on the quality of the billets and the original casting. Billet quality checks occur in real-time through process parameter control and post-production through macrographic, inclusion, and mechanical analysis. All quality control analysis results are entered into the internal computer portal where they can be cross-referenced with automatically collected process parameters.

TECHNICAL DATA

Acciaierie di Calvisano

| SECTION mm | WEIGHT Kg/m | LENGTH OF BILLETS m | MINIMUM LOT t |

|---|---|---|---|

| 120 | 110 | 3 - 14 | 80 |

| 130 | 131 | 3 - 14 | 80 |

| 140 | 153 | 3 - 14 | 80 |

| 150 | 177 | 3 - 14 | 80 |

| 160 | 200 | 3 - 14 | 80 |

Steel Quality

- Quenched and tempered steels

- Spring steels

- Nuts and Bolts steels

- Cold Heading steels

- Case-hardening steels

- Surface-hardening steels

- Low-alloy slip resistant steels

- Microalloyed steels

- Reinforcing steels according to major world standards

- Non-alloyed structural steels (carbon steels)